Preventive & Predictive Maintenance

Contact Info

Need service? Our team is ready to assist.

+91 9289825952

24/7 Support for Your Business

nc@stellerenergy.in

24/7 Support for Your Business

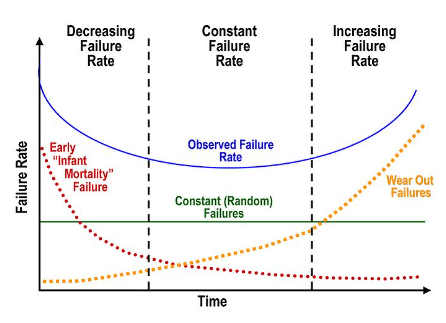

Predictive maintenance lets you monitor equipment health to avoid future failures during operation. It uses predictive algorithms with data from equipment sensors to estimate when your equipment will fail. It also pinpoints the root cause of problems in your complex machinery and helps you identify which parts need to be repaired or replaced. This way, you can minimize downtime and maximize equipment lifetime.

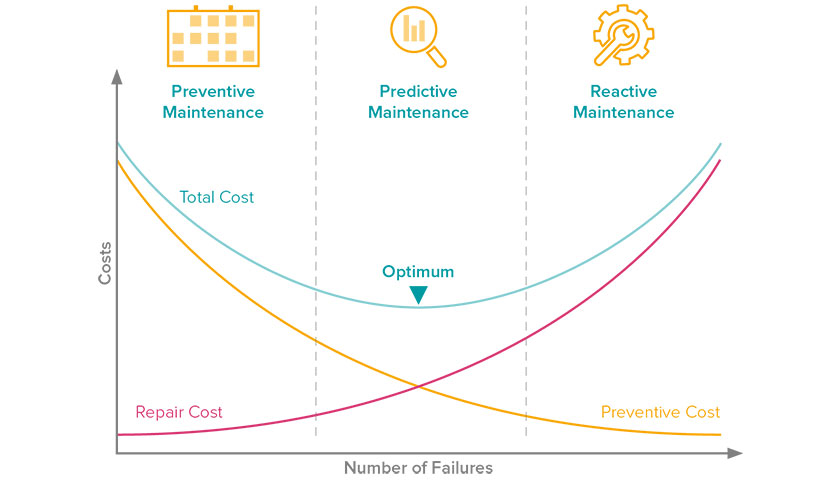

Maintenance operations ensure mechanical systems remain in working order, but not all maintenance strategies are created equal. Two common approaches are preventive maintenance vs predictive maintenance, each with its unique methods and advantages.

As a part of the digitalization process of manufacturing, the Industrial Internet of Things (IIoT) employs smart sensors and AI/ML algorithms to enhance production and industrial processes. Every machine communicates through several measures such as vibration, temperature, voltage, pressure, and sound. The only way to understand them is by converting the raw data into meaningful diagrams through data analysis. This is what the whole predictive maintenance (PdM) concept aims to achieve.

Choosing the Right Maintenance Strategy

Preventive Maintenance

Preventive maintenance is a proactive approach to equipment maintenance that involves regularly scheduled inspections, servicing, and replacement of components. This approach is designed to prevent equipment failure by addressing potential issues before they lead to a breakdown. The primary goal of preventive maintenance is to increase the lifespan of equipment and reduce the likelihood of unexpected failures. It aims to eliminate common causes of equipment breakdown, such as wear and tear, through timely maintenance. Preventive maintenance is like the routine check-ups we receive from our doctors. Just as regular health check-ups can identify and address potential health issues before they become severe, preventive maintenance in mechanical engineering prevents equipment problems before they disrupt operations.

You’re most likely familiar with preventive maintenance (PM). The theory behind preventive maintenance is to take regular steps to prevent problems before they occur. Preventive maintenance has several characteristics:

- Is planned at regular intervals.

- Requires machine downtime to carry out.

- Often consists of a checklist including equipment and component inspection, calibration, cleaning, repair and replacement.

- May occur at different intervals — your facility may have a daily regimen of machine cleaning and inspection at the beginning and end of shifts cycles and may also have more comprehensive semiannual/annual checks.

- Occurs even if identifiable issues are present.

Essentially, preventive maintenance is a collection of best practices and averages that zeroes in on an identified interval that gives you the best odds of catching issues before they start. It continues to be practiced because it is highly effective for many organizations.

Predictive Maintenance

Predictive maintenance, on the other hand, takes a different approach. It relies on advanced monitoring and diagnostic tools to predict when maintenance is needed. Rather than following a fixed schedule, it focuses on the actual condition of the equipment. Predictive maintenance aims to maximize the lifespan of equipment while minimizing maintenance costs. This approach aims to identify potential issues at their earliest stages, allowing for targeted maintenance activities and reducing unnecessary maintenance. In predictive maintenance, sensors are used to monitor various parameters, such as vibration, temperature, and oil quality. By analyzing the data collected in real-time, engineers can predict when a particular component, like a bearing, is likely to fail. This allows them to schedule maintenance for that specific component, avoiding unplanned downtime.

Predictive maintenance (PdM) is a growing field with options for connectivity and data collection continuing to be developed. In fact, the McKinsey Global Institute reports that implementation of PdM practices across manufacturing will have a $240-$627 billion cost savings across the industry. Like preventive maintenance, it is a proactive approach. The main difference between preventive and predictive maintenance is that predictive maintenance utilizes condition-monitoring equipment to assess the performance of assets through a more real-time, data-driven approach, therefore, identifying the potential for issues before they occur.

While preventive maintenance relies on best practices and historical data, predictive maintenance takes measurements from machine operations as they are occurring and uses this data to raise red flags when indications of a problem are noted. In summary, predictive maintenance:

- Is proactive.

- Can be performed as the machines are running in their normal production modes.

- Identifies and addresses potential problems, allowing maintenance to occur before a failure happens.

- Relies on interconnected measurement and data collection systems as well as tools and personnel to analyze that data.

Key Differences Between Predictive Maintenance and Preventive Maintenance

The fundamental differences between preventive and predictive maintenance lie in their approaches to addressing equipment health. Preventive maintenance is a schedule-driven strategy that follows a predetermined plan, regardless of the actual condition of the equipment. It involves regular inspections and maintenance activities that are often based on historical data and industry best practices. Predictive maintenance, conversely, is condition-based. It relies on real-time data and advanced monitoring tools to predict when maintenance is needed. This key distinction means that preventive maintenance is somewhat reactive, whereas predictive maintenance is proactive.

| Preventive Maintenance | Predictive Maintenance | |

| Approach | Scheduled maintenance based on time or usage. | Condition-based maintenance that relies on real-time data. |

| Maintenance Timing | Fixed schedule. | Based on equipment condition. |

| Goal | To prevent equipment breakdowns by replacing components proactively. | To predict maintenance needs and minimize unscheduled downtime. |

| Cost-Efficiency | May lead to unnecessary part replacements. | Generally more cost-effective due to targeted maintenance. |

| Use of Technology | Typically requires basic monitoring equipment. | Requires advanced monitoring tools and data analytics. |

| Industry Applicability | Suitable for less critical equipment or simple systems. | Ideal for complex and high-value machinery. |

| Downtime Impact | Potential for higher unplanned downtime. | Minimizes unplanned downtime. |

| Initial Investment | Lower upfront investment. | Higher initial cost for technology and training. |

| Data Reliability | Less reliant on real-time data. | Highly reliant on accurate and real-time data. |

| Skill and Expertise | Requires basic maintenance skills. | Demands advanced data analysis and predictive skills. |

| Potential for Over-Maintenance | Common issue due to fixed schedules. | Rare, as maintenance is based on actual equipment condition. |

Benefits Comparison

Preventive maintenance has its own set of advantages. It offers a sense of security, as regular inspections and part replacements can reduce the risk of sudden breakdowns. It’s well-suited for critical components or systems that are known to have a limited lifespan, and for industries where unplanned downtime can result in substantial losses.

Predictive maintenance, while requiring more advanced technology and expertise, comes with its own compelling advantages. It excels in optimizing maintenance costs by focusing on actual equipment condition, not predetermined schedules. This leads to improved overall equipment effectiveness (OEE), lower operating costs, and a longer equipment lifespan. Predictive maintenance solutions utilize condition monitoring and advanced data analysis to anticipate failures, ensuring that maintenance is performed only when necessary.

| Benefit | Preventive Maintenance | Predictive Maintenance |

| Increased Equipment Lifespan | Extends equipment life by replacing parts before failure. | Maximizes equipment life by targeting maintenance only when necessary. |

| Reduced Downtime | Reduces the likelihood of unexpected breakdowns and downtime. | Minimizes unplanned downtime by addressing issues proactively. |

| Cost Control | Easy budgeting due to regular, predictable maintenance costs. | Lower overall maintenance costs due to precision and reduced part replacements. |

| Improved Safety | Enhances safety by reducing the risk of equipment failures. | Supports a safer working environment through proactive issue identification. |

| Equipment Reliability | Increases overall equipment reliability. | Boosts equipment reliability by addressing specific issues early. |

| Production Efficiency | Ensures smoother production processes by preventing disruptions. | Optimizes production efficiency by minimizing downtime. |

| Simplicity and Familiarity | Simple to implement, relies on established schedules. | May require initial technology investment but offers long-term benefits. |

| Suitable for Critical Components | Suitable for critical components with known maintenance needs. | Ideal for complex and high-value machinery where precision is essential. |

| Quality and Consistency of Output | Maintains consistent product or process quality. | Enhances product quality by reducing equipment-related variations. |

| Overall Equipment Effectiveness (OEE) | Supports OEE by reducing unplanned downtime and equipment losses. | Maximizes OEE by minimizing downtime, improving quality, and increasing speed. |

Preventative maintenance vs. predictive maintenance

Preventative maintenance | Predictive maintenance | |

| Is considered to be | Planned maintenance | Proactive maintenance |

| Focuses on | On the environment (people, tools, and processes) | On the assets (parts and sensors) |

| Means to | Prevent damage by performing timely repairs or replacements | Predict when assets need maintenance |

| Uses | Scheduling software to notify teams or individuals of upcoming equipment maintenance | Predictive maintenance technology to address potential problems and schedule corrective maintenance before a failure occurs |

| Improves | Asset performance and asset health | Inventory efficiency since machine parts are not run to failure and are also not replaced too soon |

| Requires | Machine downtime | Does not often require machine downtime, and if it does, it’s generally short |

| Examples | Part replacement and equipment repair | Vibration analysis and thermal analysis |

KEY FEATURES

Unlocking Efficiency: Exploring Maintenance Connection's Dynamic Features

As the world’s leading provider of workplace and asset management software for unifying the built environment, we know what it takes to create CMMS software that works for your business – no matter the sector.

- Remote Asset Management, Anytime, Anywhere

Unlock seamless asset control with MC’s intuitive mobile app, granting your team the power of remote access and real-time updates. Stay ahead with customisable notifications for work orders and asset status, and breeze through maintenance scheduling with automated alerts, backed by detailed repair histories and manuals.

- Parts Management: Precision Placement, Always

Master the art of parts organisation, ensuring your technicians always have the right components at their fingertips. From streamlined planning to proactive tracking, prevent costly failures and maximise efficiency. Say goodbye to downtime woes and hello to enhanced predictive maintenance.

Seamless Reporting & Analytics: Effortless Compliance

Ease audit worries by effortlessly providing auditors with precise records and documentation. Access safety procedures, asset manuals, inventory details, and maintenance histories at the click of a button. Ensure compliance effortlessly, leaving auditors and inspectors impressed and your operations running smoothly.

Choosing the Right Maintenance Strategy

Selecting the right maintenance strategy involves considering various factors. These include the criticality of the equipment, the impact of equipment failure on production, safety considerations, and regulatory requirements. Additionally, the budget available for maintenance and the existing infrastructure for data collection and analysis play a pivotal role in the decision-making process. To guide businesses in making the right choice, a structured decision-making process is necessary. This process should include a comprehensive evaluation of the equipment, the industry’s best practices, and a cost-benefit analysis. Implementing a hybrid approach, combining preventive and predictive maintenance, can also be a viable option, allowing businesses to reap the benefits of both strategies.

At Steller Energy and Constructions, we are dedicated to empowering power plants to achieve peak performance, enhance operational efficiency, and ensure long-term success.

Offices

Registered Office: FF-4, Sushantlok -1 Sushant Vyapar Kendra,Gurgaon, HR-122009

Corporate Office: Works: Mustakil No. 25/10, 26/6/1, 7/1/1, Deoli Mandkaul Road, Baghola, Palwal, HR-121102